Pulsed Versus Continuous Wave Lasers

Block Engineering's mid-infrared quantum cascade lasers are "pulsed" rather than "continuous wave." What do these terms mean? And what are the advantages of a pulsed laser?

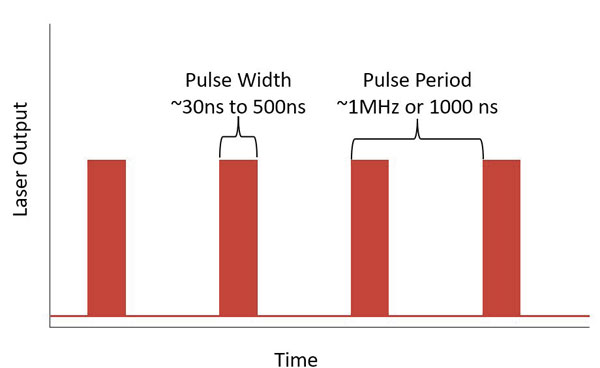

Pulsed lasers emit light in extremely rapid bursts, or pulses, with pauses between pulses. The time period of a pulse is measured in nanoseconds (billionths of a second).

Pulsed lasers emit light in extremely rapid bursts, or pulses, with pauses between pulses. The time period of a pulse is measured in nanoseconds (billionths of a second).

In Block's quantum cascade lasers, the time (or "width") of each pulse can be set between 30 nanoseconds and 500 nanoseconds.

By contrast, continuous wave lasers do not emit light in pulses. Instead, light is continually and uniformly released, much like a shining incandescent lightbulb.

Why Choose a Pulsed Laser?

The primary benefit of a pulsed design is that heat from the laser is given time to dissipate. Instead of keeping the laser "on" and "hot" continuously, the gap between pulses allows for significant conduction cooling.

In the case of Block's lasers, this means that bulky external air and water cooling systems are not needed to draw heat away from the laser.

In fact, Block's QCL packages are thermoelectrically cooled without any external fans or other moving parts. Because of that, our systems are extremely compact, less expensive than actively-cooled continuous wave (CW) lasers, and do not require power-hungry and mechanically vulnerable cooling systems.

Another benefit of reduced heat is that pulsed laser beams can protect the target of the laser from thermal damage. Because Block's lasers are often used to analyze delicate biological tissues, detect trace chemicals, and power infrared microscopes, this is important.

Tissue samples that might be damaged by a hotter CW laser can be interrogated gently over time by a cooler pulsed laser. The risk of thermal interference is also reduced, increasing the measurement accuracy of chemical signatures.

Because Block's lasers are primarily used in spectroscopy, research, and biomedical analysis applications, pulsed beams are usually preferred by our customers.

A Continuum

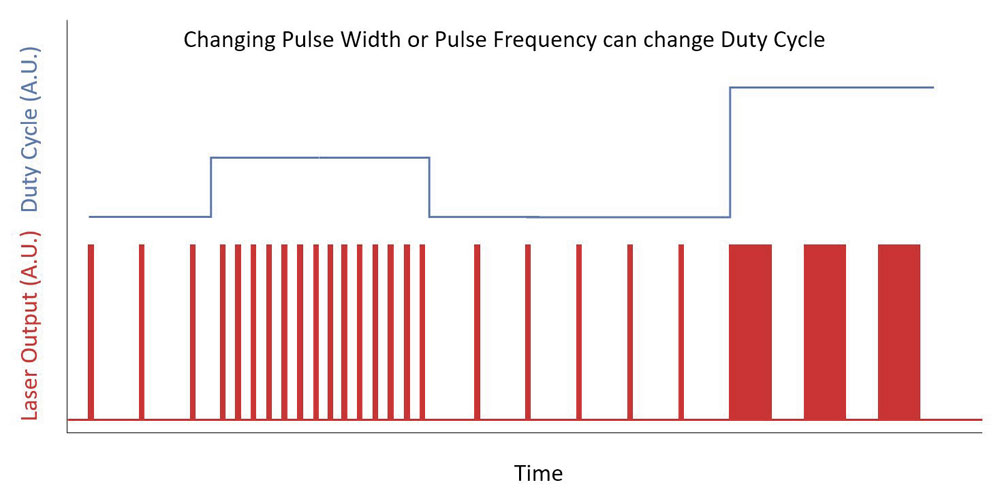

The choice between pulsed and continuous wave lasers isn't binary. Because pulse width and period can be programmed, it's possible to increase the number and width of laser pulses in time, effectively bringing a pulsed laser's duty cycle closer to CW.

We use the term "duty cycle" to describe the percent of time that the laser is emitting light while on. For a CW laser, the duty cycle is 100%. For a pulsed laser, the duty cycle might be tens or just a few percentage points, depending on how much optical power is required to analyze the sample while also considering heat dissipation requirements.

The duty cycle of Block's QCLs can be controlled through preprogrammed laser fire pattern, allowing for modification of pulses.

Some applications require greater light; others need less heat or thermal interference. The flexibility of pulses and duty cycles can help our laser customers find the ideal balance.

Please contact us to discuss your application needs, or visit our MiniQCL lasers for manufacturers or LaserTune for researchers pages for technical information on our mid-infrared lasers.